Do you want to have a design printed on a t-shirt but would like to do it yourself? If so, you'll typically need to decide between sublimation and heat transfer. This entails choosing between transfer paper and sublimation paper. Even though you may always send your design to a print-on-demand company to be created by experts, you could discover that doing it yourself is quicker and less expensive.

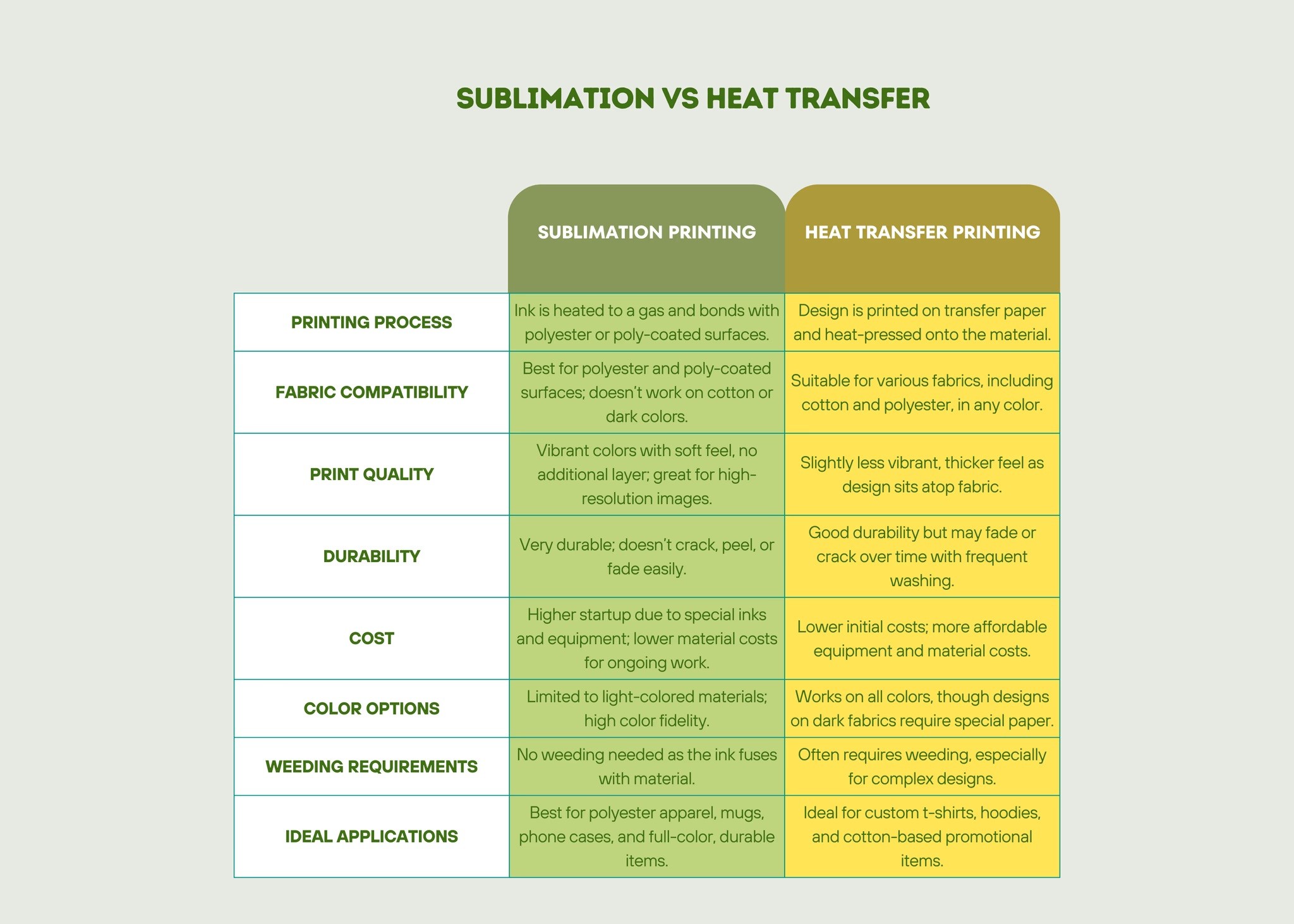

The main difference between sublimation and heat transfer printing lies in their processes and material compatibility; sublimation integrates ink into polyester fabrics, resulting in vibrant, durable prints without adding a layer, while heat transfer printing applies designs on various materials, including cotton, but may feel like an additional layer and is less durable. Your choice should depend on the specific fabric type and desired print quality.

Are you having trouble deciding between sublimation and heat transfer for your upcoming project or business? Today, we examine some of the distinctions between printing t-shirts using transfer paper and sublimation. Continue reading to learn more about Sublimation vs. heat transfer for beginners!

Understanding what is sublimating printing

In the sublimation printing process, heat and pressure turn the ink into a gas that adheres directly to the substrate. This method produces a long-lasting, superior print that blends in perfectly with the substrate or cloth. Sublimation is a little particular about the materials it uses.

Polyester textiles or objects with a unique polymer coating are ideal for it. The nature of the sublimation process, which necessitates materials that can tolerate high temperatures and form an efficient binding with the sublimation inks, is the cause of this constraint.

The longevity of sublimation is one of its most notable benefits. The prints defy fading and cracking over time and are sharp and colorful. Because of this, sublimation is a great option for products like sportswear or personalized mugs that will be subjected to a lot of wear and tear.

You will require some tools and materials to begin sublimation. A printer made to use sublimation ink or toner is the first need. The smooth and accurate transfer is ensured by the formulation of these inks, which change from solid to gas without becoming liquid.

Sublimation printing is not compatible with all inkjet printers, thus it's crucial to confirm with your model before starting. You might want to get a sublimation printer or an inkjet that is compatible with sublimation if you believe you would like to do sublimation printing more frequently.

To apply the required heat and pressure to finish the sublimation process, you'll also need a heat press. The beautiful and durable results make the initial expenditure worthwhile, even though it may be greater than with certain other printing techniques.

Pros:

The sublimation method produces full-color with high-definition prints that are not easily faded or cracked.

The prints are incredibly durable, sometimes outlasting the cloth they are printed on, because of the way the ink fuses with the material.

Sublimation prints are as smooth and soft as the material's original texture, and there isn't any raised surface.

Cons:

Its restriction to polyester textiles or poly-coated objects is its main flaw.

Additionally, sublimation prints only work on light-hued (preferably white) materials since they do not appear effectively on dark or colored substrates.

Due to the nature of the procedure, print details and edges are not as sharp as they are with other heat transfer techniques.

Best used for:

Printing full-color designs on light-colored polyester textiles. Even used on hard surfaces with poly coatings. It's a well-liked technique for producing vivid and durable prints on a variety of goods.

Understanding what is heat transfer

Heat transfer printing, as the name implies, is printing using heat transfer paper. The procedures for transferring the print onto a t-shirt after printing are essentially the same as those for sublimation printing. Place your design face down on the shirt after printing it in reverse onto the heat transfer paper.

Heat transfer is a flexible technique that uses pressure and heat to imprint a design onto a variety of surfaces. The design is transferred to the finished object by applying differing amounts of heat and pressure, typically using a heat press machine, after it has first been printed onto another media (such as vinyl, paper, or film).

The versatility of heat transfer printing is what makes it so lovely. The phrase refers to a number of methods, such as DTF (Direct-to-Film transfers), screen printed transfers (plastisol ink), heat transfer vinyl or HTV (cut vinyl or printed vinyl), and heat transfer paper (inkjet, laser, or sublimation).

With distinct features, benefits, and drawbacks, each variation gives customers a multitude of choices to help them reach their goals. The unique qualities and outcomes of dye sublimation printing, sometimes referred to as "dye-sub" or just sublimation, make it stand out.

Pros

Heat transfer paper's price and user-friendliness are its main advantages.

It is quite accessible for novices or small-scale enterprises

It only requires a printer (either an inkjet or laserjet printer, depending on the paper) and a heat press or iron.

Cons

In comparison to alternative heat transfer techniques, heat transfer paper may not be as durable.

Several washings may cause designs to fade or crack.

the adaptability of some heat transfer paper kinds may be limited when applied to dark clothing.

The best applications:

For heat transfer paper include small-scale manufacturing, crafts, and do-it-yourself projects. It's great for quickly making personalized mugs, clothing, and other products.

Pointing the difference between heat transfer and sublimation

Process

Ink is directly bonded to the material during sublimation. Using this technique, the ink penetrates the fabric or substrate and becomes a part of its structure by turning into a gas under pressure and heat. This results in a smooth, long-lasting print that is incorporated into the fabric.

Applying a distinct layer to the material's surface is known as heat transfer. After printing the pattern onto transfer paper, you will use pressure and heat to adhere it to the substrate. In contrast to sublimation, the design forms an extra layer by sitting on top of the cloth. You can get Custom t-shirt printing by using both methods.

Equipment and costing

Since you can use any inkjet or laser printer you already have at home, heat transfer printing is really affordable to begin with. In addition, you will need a heat press, which can be purchased to begin with, the clothes you plan to decorate, and the heat transfer paper.

In comparison, sublimation printing is more costly, but it has decreased recently, while the price of the heat press has not changed. Purchasing a sublimation printing starter kit, which includes the sublimation printer, paper, required product designer tool, and a sample set of products to print on, is an economical choice.

Feel and print quality

Sublimation gives the garment a better feel and unparalleled endurance because the printed design is actually a part of the cloth rather than a coating on top.

You can feel the layer on top when using heat transfer printing, and it may fade or crack after several washing. However, you may create and market print goods with a softer feel and more durability rather rapidly by spending money on better heat transfer sheets and hiring an online web designer.

Fabric compatibility

You cannot use sublimation ink on clothing made entirely of cotton since it only binds to polyester. Although poly-cotton fabrics can be used to some degree, the transfer quality would not be as vivid.

Additionally, because sublimation does not require additional layers on top of the fabric, light-colored or white clothing is required for the design to be visible. Conversely, heat transfer printing can be used on mixed, polyester, and cotton textiles as well as clothing in any color.

Color compatibility

If you want to produce a specific design, such as a brand logo or a portrait, sublimation printing is perfect because it allows you to use complete colors. The full-color effect may not always be achieved with heat transfer printing.

Purchasing higher-quality heat transfer paper is necessary if you wish to use heat transfer to print images or logos. For photo printing, inkjet transfer papers are usually your best option.

Durability

For, Sublimation vs. heat transfer durability Instead of applying a layer on top, sublimation uses a technique where the ink becomes a part of the cloth. As a result, the transfer has unparalleled feel and longevity. Heat transfer paper, on the other hand, adds a layer to the clothing. Physically palpable, this extra layer is less resilient than sublimation and is susceptible to fading and cracking with repeated washing cycles.

It's crucial to remember that different heat transfer sheets have different qualities; some may feel softer and be more durable than others. For people who have never used an inkjet printer before.

Weeding

Sublimation printing is a naturally self-weeding process because the design is printed directly onto the fabric. Except for some "two-step" laser transfer papers, heat transfer papers usually do not self-weed. This implies that the majority of heat transfer papers will have a noticeable background surrounding the design in the paper's shape.

To remove this backdrop, you will need to trim around the image, especially if the cloth is black enough to see it well. You can still physically feel the background even though it is less noticeable when the fabric is white or light in color.

Applications

Because of its adaptability, heat transfer paper can be used on hard substrates with flat surfaces in addition to textiles. This gives you endless creative options for decorating a variety of objects, including glass, pottery, and wood.

With a unique poly-coating, sublimation printing may be used on a range of hard surfaces. Although a special coating is still required, sublimated objects are now more durable like Sublimation printing on mugs. Adding hard-surface sublimation items to their offerings will undoubtedly help them expand their product offerings.

Which to choose?

Our investigation of heat transfer techniques revealed their adaptability and capacity to produce vibrant, detailed prints. However, the method and materials selected have a significant impact on the print quality, hand feel, and durability. Dye sublimation is distinguished by its unparalleled color brightness and endurance. Nevertheless, its capabilities are restricted to objects with poly coatings or light-colored polyester fabrics.

Which is superior, then? It all depends on your particular demands. For bright, long-lasting designs on polyester or poly-coated materials, sublimation is the undisputed victor. However, heat transfer techniques are the best option if your project calls for versatility across a range of materials, or if you're working on a smaller scale or with a more constrained budget.

Checklist for choosing

Think about utilizing sublimation for:

● Items coated in polyester or polymers

● Durable prints

● Long-lasting outcomes

● smooth, expertly finished

● Large budget

Think about applying heat transfer for:

● Adaptability in the positioning of the design

● Reduced setup costs

● Easy, uncomplicated technique with food outcomes

● Limited budget

Conclusion

Your adventure into the realm of heat transfer printing continues as we wrap up our comparison of sublimation vs heat transfer. With the knowledge gained from this tutorial, you may make informed choices.

There are several things to take into account when choosing between the heat transfer and sublimation methods for your t-shirt design. While sublimation designs require suitable equipment to print, heat transfer prints are easy to develop and may be produced with either an inkjet or a laser printer.

If you want to make unique designs and prints use WTPBiz web to print tools for your better printing results.

FAQs

What is the main difference between sublimation and heat transfer?

Sublimation gives the garment a better feel and unparalleled endurance because the printed design is actually a part of the cloth rather than a coating on top. You can feel the layer on top when using heat transfer printing, and it may fade or crack after several washing.

Can I use sublimation on cotton shirts?

No, sublimation is only suggested on polyester or poly cotton t-shirts because of its printing techniques and adaptability.

What types of materials can I sublimate on?

You can sublimate on all materials except cotton. You can use it for ceramic, wood, glass, polyester and many more.

Which method is more durable: sublimation or heat transfer?

Sublimation is durable compared to heat transfer because of its printing technique. The prints are injected into the surface making it durable.

What are the start-up costs for each printing method?

The sublimation method needs high technology while heat press needs minimal and no technology. Making sublimation costlier compared to heat press.

Which method is best for printing photos on t-shirts?

If you want to print proper photos then a heat press is suggested since it layers the whole image on the surface of the t-shirt.

FAQs