Introduction

The advantage of using t-shirt sublimation printing is due to colorful printing, durability, and flexibility, especially in the apparel industry. This technique involves the use of heat for the transfer of ink to polyester fabrics to create designs that cannot be washed, peeled, or cracked. It should not be confused with screen printing or heat transfer, where ink is directly transferred in a heated manner onto the substrate fabric, as sublimation printing discharges the ink particles into tiny gas molecules that penetrate into the weaves of the fabrics.

The outcome is a vibrant full-color print that does not fade in its brightness and is highly resistant to wash-off. However, the duration for washing and exposure to ultra-vigorous ultraviolet rays and the fabric material may affect the durability of the print. This article goes a step forward in unpacking the sublimation process, the gains that come with the process, as well as the concerns, which include T-shirt sublimation prints fading and how one can dodge it in order to conserve the t-shirts which have been printed in this sublimation process. In any case, the opportunity to get acquainted with the main provisions of sublimation printing will be useful for both business people and lovers of do-it-yourself creativity.

Overview of Sublimation Printing

What is Sublimation Printing?

Sublimation printing is a digital printing technique that has been carried out using heat and ink for transferring designs onto fabrics and other substrates. What distinguishes sublimation is that the ink proceeds from a solid form into a gaseous state without the intermediary stage of liquid, which distinguishes most forms of printing. This allows it to penetrate the fibers of the material and become bonded to them.

Design Creation: The design initially to be put on the fabric is printed directly onto specially fabricated dye-sublimation transfer paper.

Heat and Pressure Application: In this method, the design is printed on a material and fixed on the fabric by heat pressing through a phase in temperatures of 375 degrees Fahrenheit to 400 degrees Fahrenheit.

Permanent Bonding: The heat has the effect of preparing the fabric by making the pores of the fabric open to allow the settling of the gaseous ink into the fabric fibers. After the solvent ink has been deposited onto the fabric, the print hardens once it becomes cold, making it very hard to fade or wear off.

Benefits of Sublimation Printing

Durability: Unlike other methods of printing, sublimation prints do not come off easily, crinkle, or fade if conditions for printing are well observed.

Vivid Colors: Full color and very high image resolution can be achieved through the process of sublimation, reducing the need for a seam.

Versatility: It can be used on different items, clothes, t-shirts, mugs, cell phone cases, among others.

Environmentally Friendly: It takes less ink and creates little waste when compared to other printing methods.

However, sublimation printing is not exempted from some challenges, such as T-shirt sublimation prints fading. Now it is high time to discuss the main causes of this problem.

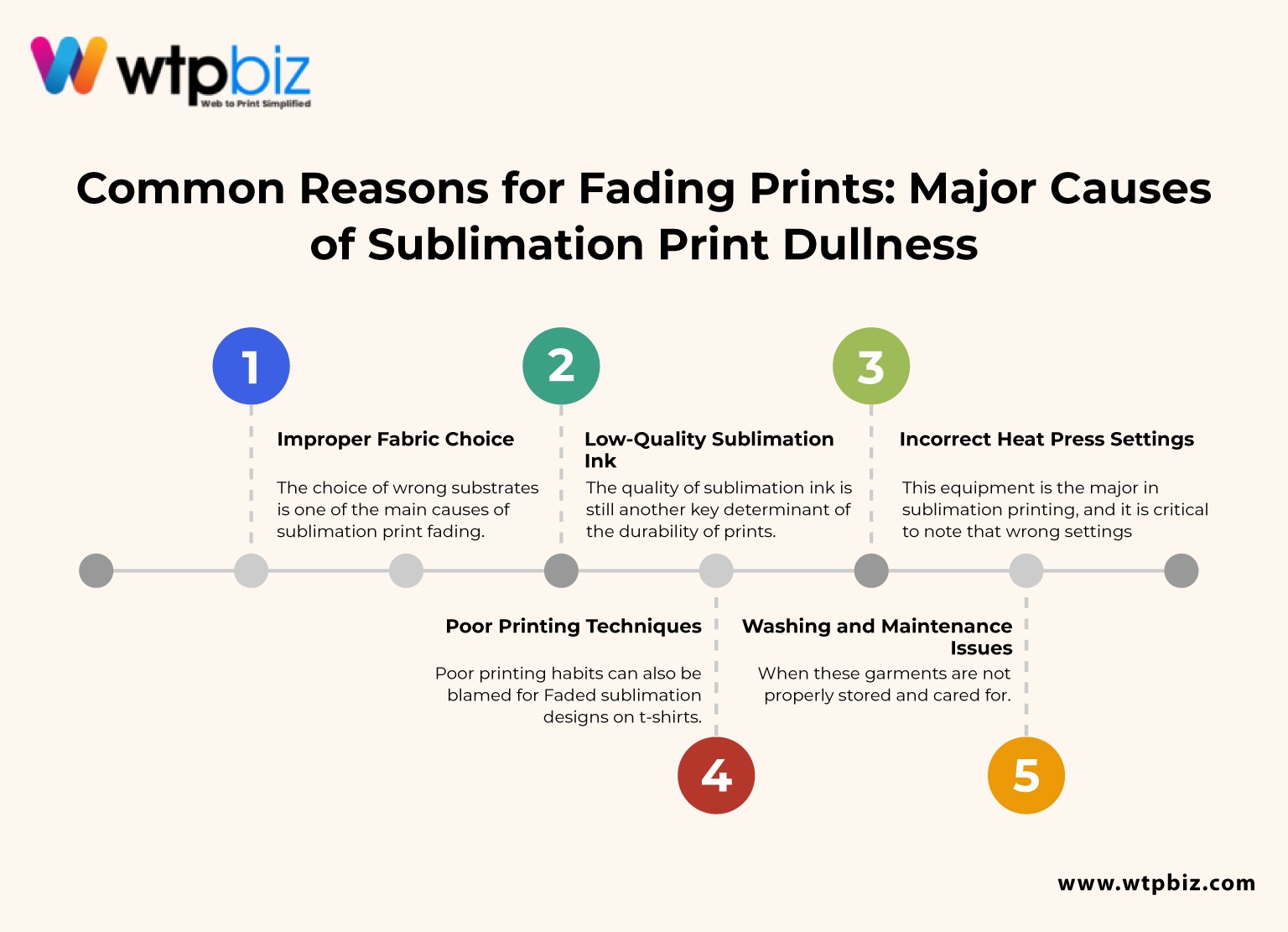

Common Reasons for Fading Prints: Major Causes of Sublimation Print Dullness

Here are the major reasons for sublimation print fading and losing their brilliance, explained in detail:

1. Improper Fabric Choice

The choice of wrong substrates is one of the main causes of sublimation print fading. Sublimation is most effective on polyester or polyester blend since the sublimation dye is chemically deposited on the polyester fibers during the heat transfer process.

Why Polyester Matters: Polyester is also flexible and has the capability to expand its surface in contact with heat, and thus the ink simply absorbs into the fabric. This gives the prints a long-lasting effect.

Impact of Other Fabrics: Materials such as cotton or wool do not possess such chemical compatibility. Their use results in prints that blur quickly since the dye cannot adhere to any of the materials.

Solution: For situations when you have to choose material, sublimation printing always works best on 100% polyester or garments that have at least 50%-60% polyester composite.

2. Low-Quality Sublimation Ink

The quality of sublimation ink is still another key determinant of the durability of prints.

Effect of Substandard Ink: Most of the cheap or low-quality inks are unlikely to have the pigments or the required formulation that can enable them to survive washings and the harsh effects of weather such as sunrays. Consequently, prints can fade, losing their color or may look pale after few uses.

Importance of Premium Inks: Special adhesives used for these signs are produced to adhere well to polyester and have qualities of not easily fading sublimation prints on shirts in the long run.

Solution: Sublimation ink is not inexpensive; thus, purchasing high-quality durable inks should not be overlooked.

3. Incorrect Heat Press Settings

This equipment is the major in sublimation printing, and it is critical to note that wrong settings of the heat press affect the print quality.

Temperature: Sublimation printing needs heat to turn the ink into gas so that it can be integrated with the materials. Using too little heat results in incomplete transfer, while using too much heat can cause the design or the fabric to burn.

Pressure and Time: Too little pressure or wrong timing can result in uneven transfers, leading to faded or blotchy prints.

Solution: Always adhere to the guidelines that are given in the manufacturer’s instructions for the best bet relating to temperature, pressure, and time.

4. Poor Printing Techniques

Poor printing habits can also be blamed for faded sublimation designs on t-shirts.

Alignment and Preparation: Most often, there may be mismatched designs or if the fabric was not properly prepared for the printing process.

Printing Errors: This leads to poor image quality and uneven prints; some of the steps that should be followed may be missed, while others might use low-quality transfer paper.

Solution: Maintain a specific print process, purchase the best quality transfer paper, and align the T-shirt appropriately for clear, bright imprinting.

5. Washing and Maintenance Issues

When these garments are not properly stored and cared for, sublimation printing does nothing but cause its service life to decrease significantly.

Frequent Washing: Cotton products should not be washed frequently, as frequent washing washes off the color, particularly if the washing is done in hot water.

Harsh Detergents: Leisure business wears can also lose their color because harsh detergents can fade the dye from the fabric.

Sunlight Exposure: UV rays, when exposed for a long time, have a very negative effect on sublimation dyes, causing them to fade.

Solution: Suggest customers to desist from drying sublimation-printed garments through direct sunlight, wash them using cold water, and gentle detergents.

Preventive Measures to Avoid Fading in Sublimation Prints

Sublimation printing has become rife for its effectiveness in creating bright and durable images on different materials, but mostly t-shirts. However, sublimation printing has one disadvantage – the prints can easily fade away, which is a concern to many users. This means that providing a background to the causes of this problem or even avoiding them will help in the improvement of the lifespan of the prints.

Proper Washing Techniques

Washing is one of the most common issues with sublimation prints that people make while dealing with sublimation prints, and it can, therefore, be regarded as its main cause. General washing or using hot water and strong chemicals on garments that have been sublimation printed will lead to ink subsiding from the garment. To avoid this, wash clothing in cold or lukewarm water and make sure you use the gentle cycle. Another measure that can be used to ensure that the print does not fade is washing one's hand before touching the print. Do not use blanching or creams that contain bleach and fabric softeners that tend to fade printed materials.

Reducing UV Exposure

Sublimation prints fade when exposed to direct sunlight or ultraviolet (UV) light for quite a long time. Some customers dry their clothes where they hang them and under direct sunlight, which hastens fading. Instead, recommend hanging clothes to dry in the shade or indoors. Applying UV protection sprays also has the capability to protect the prints from direct sun rays.

Quality of Materials

The type of material to be used is one of the decisive factors when it comes to the lifespan of sublimation prints. Sublimation is perfect on 100% polyester fabrics in that it attaches to the fibers through the ink. Using prints on blended fabrics may also have some issues with the quality of the prints. Always make sure hard surfaces come with the right polyester layer. Sublimation material should not have too many layers of polymer coatings because they hamper the sublimation process and dull the image.

Optimal Heat Press Settings

Sublimation printing works on the basis of heat, pressure, and time, but it’s all based at once. Some of the many issues associated with superheated printers include; This means that if a designer sets the heat press process incorrectly, the prints may fade or even appear to be out of focus. It is important at all times to stick to the laid-down standard temperature, pressure, and time for the material that is being utilized. The organized heat input guarantees that the ink has a good chance of bonding with the substrate.

High-Quality Inks and Equipment

The performance characteristics of the sublimation ink reflect on the durability of the printed items. Buy high-quality ink that is unlikely to cause color deterioration and is capable of giving optimum color intensity. Of course, proper care of printing equipment, including such devices as inkjet printers, also plays the same role as their daily maintenance is required. The heads that are responsible for printing must be always clear and cleaned frequently in order to prevent damaging the quality of the prints.

Managing Polymer Layers

When using polymers on non-textile substrates such as ceramics, there is the need to professionally undertake the coatings aspect. Most products, including ceramics, are protected by a polymer layer of some sort. Talking about layers, I have to mention that an extra layer may be applied here and there, which prolongs the sublimation process and influences the result. Make sure that this coat is put in the correct manner and is even for the material in question.

Conclusion

DTG is still a favorite of many t-shirt printing businesses because of the colors and adhesion of the prints. However, like checking fade factors such as washing, exposure to ultraviolet rays, and improper use of polymer coatings will all lead to fade even though the process has many merits. If you know how to keep sublimation from fading after washing, these include recommending customers to properly handle their products, avoid direct contact with heat and water, and applying some of the materials correctly. Other measures that organizations can take to increase the durability of the prints include applying appropriate care advice to the customers, avoiding heat and water contact, correct application of some of the materials, and others.

As print owners seek to expand their product line, sources such as WTPBiz's Product Designer Tool give them a useful approach. This software enhances the ability of customers to design their products without undue difficulties when using printstore solutions. Having been in business for over a decade, WTPBiz helps organizations expand operations and explore ways of increasing the returns on investment and sales. These best practices to maintain sublimation prints on t-shirts, utilizing sublimation printing, complement the right strategies and tools with better outcomes and succeeding customer expectations.

FAQs

Why do sublimation prints on T-shirts fade over time?

Fading occurs due to improper fabric selection, low-quality inks, incorrect heat press settings, or poor washing practices.

How can I prevent my sublimation prints from fading?

Use high-quality polyester fabrics, branded inks, accurate heat press settings, and follow proper washing and maintenance routines.

What is the best fabric for sublimation printing to avoid fading?

Fabrics with 100% polyester or at least 65% polyester content are ideal for t-shirt sublimation prints.

Can washing techniques cause sublimation prints to fade?

Yes, washing in hot water, using harsh detergents, or drying under direct sunlight can cause prints to fade.

Do heat press settings affect the durability of sublimation prints?

Absolutely. Incorrect temperature, pressure, or time settings can result in incomplete ink transfer, leading to faded designs.

FAQs