Hoodies are a wardrobe essential for most people since they are cozy and adaptable. They go well with almost everything and are ideal for casual or sports attire. Selecting the Best hoodies for printing is crucial, whether your goal is to sell custom hoodies or just update your wardrobe. But how can you make the best decisions when there are so many possibilities available?

We've done the legwork and put together a selection of the Best hoodies for custom printing that have been tried and true in terms of comfort, style, and longevity. Because of their excellent fit and high-quality construction, these Print-on-demand hoodies will hold up well to repeated washings and wears of your designs.

Because of this, Premium hoodies for printing are an amazing and memorable way to market your company, outfit your team, sell a ton of merchandise, or just give your loved ones and supporters something warm and cozy.

To assist you in selecting the ideal high-quality sweatshirts for printing, we'll go over the fundamentals of sweatshirt quality, contrast fabric alternatives and printing techniques, assess manufacturers, and compile best practices for maintenance and customization.

The quality of hoodies to choose

The quality of the clothing you choose to Web to Print Services matters. Superior sweatshirts are perfect for printing because of their perfect fabric weight, thread count, fit, and durability. The greatest influences on print vibrancy when printing on sweatshirts are thread count and fabric weight.

Other than the fabric, web to print solutions are also responsible for the high quality of printing. When you use optimal web to print software with advanced features, it will result in high-quality prints. Use the WTPBiz web to print solutions for your business and get the best printing outcomes.

Over 7 oz. heavier weight textiles have more cotton for ink absorption, and tight threads keep logos and graphics from fading away so they stand out. When combined, these qualities provide breathtaking visuals.

On the other hand, subtle prints are produced by sheer or light materials with few threads. Thus, weight and thread count specifications should be included in the quality benchmarks for sweatshirts that are going to be printed.

The process used to make hoodie fabric modifies its appearance, feel, and durability. Knowing the characteristics of various fabrics and fabric blends is crucial if you want to sell fantastic custom-printed hoodies in your store.

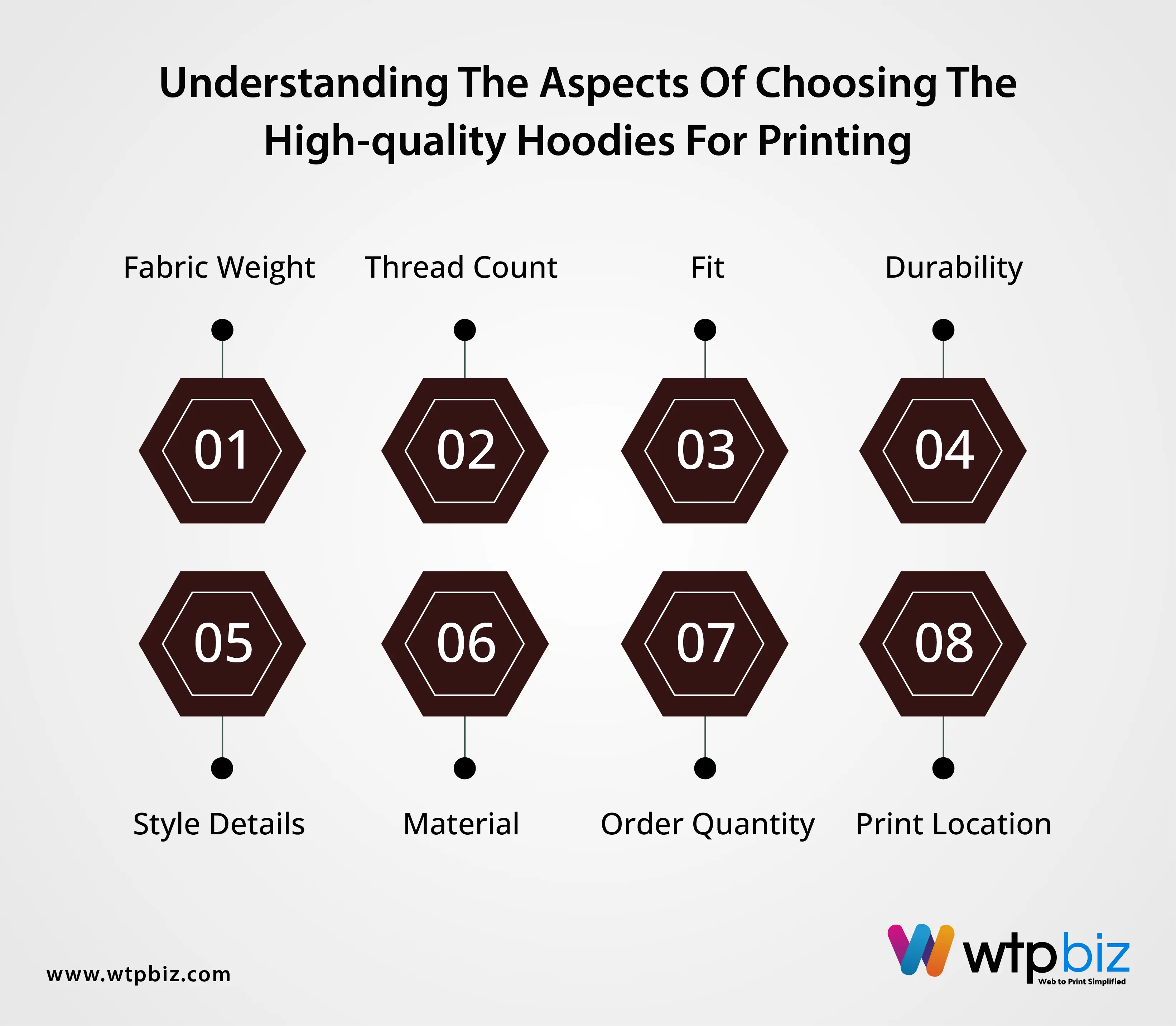

Understanding the aspects of choosing the High-quality hoodies for printing:

Fabric Weight:

choosing the right fabric is a very important step. A mid weight cloth (7-9 oz) has just enough weight to feel luxurious without sacrificing comfort. While heavier textiles can be stiff, lighter fabrics might be overly sheer. So choosing a mederight hoodie is suggested.

Thread Count:

The thread count of the hoodie is dependent on the durability of it. For vibrant Web to Print quality, a cloth with a higher thread count—typically 18–20 threads per inch—has more density. Reduced thread counts could seem garish. Try choosing the hoodie with a higher thread count.

Fit:

For durable branding, well-fitting sweatshirts maintain their shape better after numerous washings and wearing's. However if you want to go with the current trends, choosing oversized hoodies is also in trend. You can have a variety of options to choose from.

Durability:

To retain their shape, high-quality sweatshirt fabrics usually contain 80–90% cotton and a small amount of polyester. They can tolerate printing at high temperatures. Since polyester is made from synthetic fibers, chances are that it may melt or burn because of the high temperature.

Style Details:

Compared to plain pullover hoodies without decorations, items with zippers, pockets, tapered waists, and lined hoods are more expensive. While they enhance styling, these qualities are not essential for high-quality Product Designer Tool. you need to manage the style details such that it does not affect the print. Sometimes when printing, the chains and pockets come in the designs leading to misprint.

Material:

Because they are more durable and allow for better printing, hoodies made of heavier weight Soft cotton hoodies for printing blends with higher thread counts typically cost more. When compared to ordinary cotton, premium materials like fleece, blends of poly-cotton, and ring-spun cotton should be expected to cost more.

Order Quantity:

Purchasing hoodies in larger quantities lowers the cost per product. Reputable manufacturers should provide discounts for large orders. If you want to manufacture a huge lot of hoodies, then you should decide the quantity of the hoodies to be ordered.

Print Location:

You can save money on shipping and logistics by having your branding printed domestically as opposed to abroad. But if you want to have a different quality and want to sell imported printed hoodies then you may ship it from abroad. Remember that if you purchase from the nearest place, the shipping cost will be the least.

Understanding why fabric quality is the best

For the best Print On Demand print quality, the fiber content of the sweatshirt should be taken into account while choosing it for printing. Because it is soft, breathable, and evenly absorbs ink, cotton is widely considered the best cloth for printing. A blend of cotton and polyester may also be effective, with the polyester offering better shape retention.

Since rayon and modal textiles lack the structure and resilience to withstand multiple washings with a print, they are usually not the best materials to use for printing. Additionally, spandex-containing stretchy athletic materials should generally be avoided because their flexibility can eventually distort prints.

In the end, a midweight sweatshirt made of 100% cotton or 50% cotton and 50% polyester provides the ideal ratio of breathability, print brilliance, softness, and form retention so choose it as Best blank hoodies for printing. Bright color reproduction is possible without fading or distortion thanks to the high cotton content.

The weight of the cloth has a big influence on print quality when printing on sweatshirts. Less than 8 oz lightweight textiles show through and might not offer a clear print surface. Over 12 oz of heavy fabric may hinder the garment from fully absorbing the ink.

A midweight (10 oz) cloth is usually the sweet spot since it offers just the right amount of thickness to absorb vivid ink without being overly stiff or heavy. As a result, the design is able to seem solid and smooth without any discernible fabric-underlay texture.

In order to avoid bleeding or distortion in the pattern, heavier textiles also need different ink drying periods between print passes. Therefore, if you decide on a thicker 14 oz or more sweater, closely coordinate ink volumes and drying periods with your print provider. You can also use the Tshirt Designer Tool for making new designs out of it.

The thread count for sweatshirts shows how many threads were used to make one square inch of fabric. The thread count of most sweatshirts is between twenty and thirty. In general, a thread count of more than 24 is preferable for printing. More precision in the Web to Print Solutions design is made possible by the smoother surface that the higher density creates for the even transmission of ink across the cloth.

Over time, sweatshirts with a high thread count also typically become softer and more resilient. After frequent usage and washing, the tighter weave keeps its shape better and prevents pilling. Thus, give preference to blank sweatshirt options with a thread count more than 24 when choosing one for printing. Regardless of the printing technique chosen, this will offer the best print quality and longest-lasting Hoodies for DTG printing.

Conclusion

Think about the fabric composition, weight, fulfillment method, and price, of course, to get it correctly. Determine your profit margins and the price point at which buyers are willing to pay for a personalized sweatshirt from your company. Order samples to view your Custom print hoodies guide in person and assess the print quality. To make something really one-of-a-kind, think about adding imaginative embellishments like woven labels and embroidery. Care instructions are also essential; choose prints that will last and explain on how to wash them properly.

For companies looking to print high-quality prints, use the WTPBiz tool. The tool comes with all different types of features and AI capabilities, enabling you to get the best prints for all your business needs. If you want to know more about the WTPBiz tool then contact us now!

FAQ's

Q. What are the best hoodies for custom printing?

Superior cotton and polyester are excellent hoodie materials, and their combination lengthens their useful life. Here, you want to consider the kind of knit, the weight of the fabric (heavier means higher durability), and the manufacturing method.

Q. Which hoodie materials are ideal for DTG printing?

Conversely, since synthetic fabrics are made of plastic, they repel water. The best textiles to use for DTG printing include blends, light-colored polyester, cotton, organic cotton, combed cotton, and linen.

Q. How do I choose a hoodie for screen printing?

DTG printing produces the cleanest, crispest pattern when used for printing with a lot of various colors, tiny dots, or fine lines. However, screen printing is an excellent option if your designs are simpler and use fewer colors.

Q. Are cotton hoodies better for printing?

The most popular fabric is cotton. It is perfect for creating clothing for the winter because it is pleasant to the touch. A premium sweatshirt or hoodie is made entirely of cotton.

FAQs