Screen printing or silkscreen printing is a powerhouse in the world of garment printing for developing vibrant designs that last even for the longest of ages. Among them are the iconic brand labels Nike and Adidas, for the bold logos and complicated graphics on T-shirts that use only screen printing methods. One tried-and-tested technique has truly earned its name as representing quality and creativity in design.

This core process in screen printing simply puts ink on a surface via the mesh screen, blocking other areas with stencils. A versatile process that can print ink on fabric, plastic, wood, or metal, among others, it is highly used in T-shirt printing and the production of promotional materials. Among its key advantages, its toughness, along with strong color saturation and cost-effectiveness, particularly for large volumes, can't be matched.

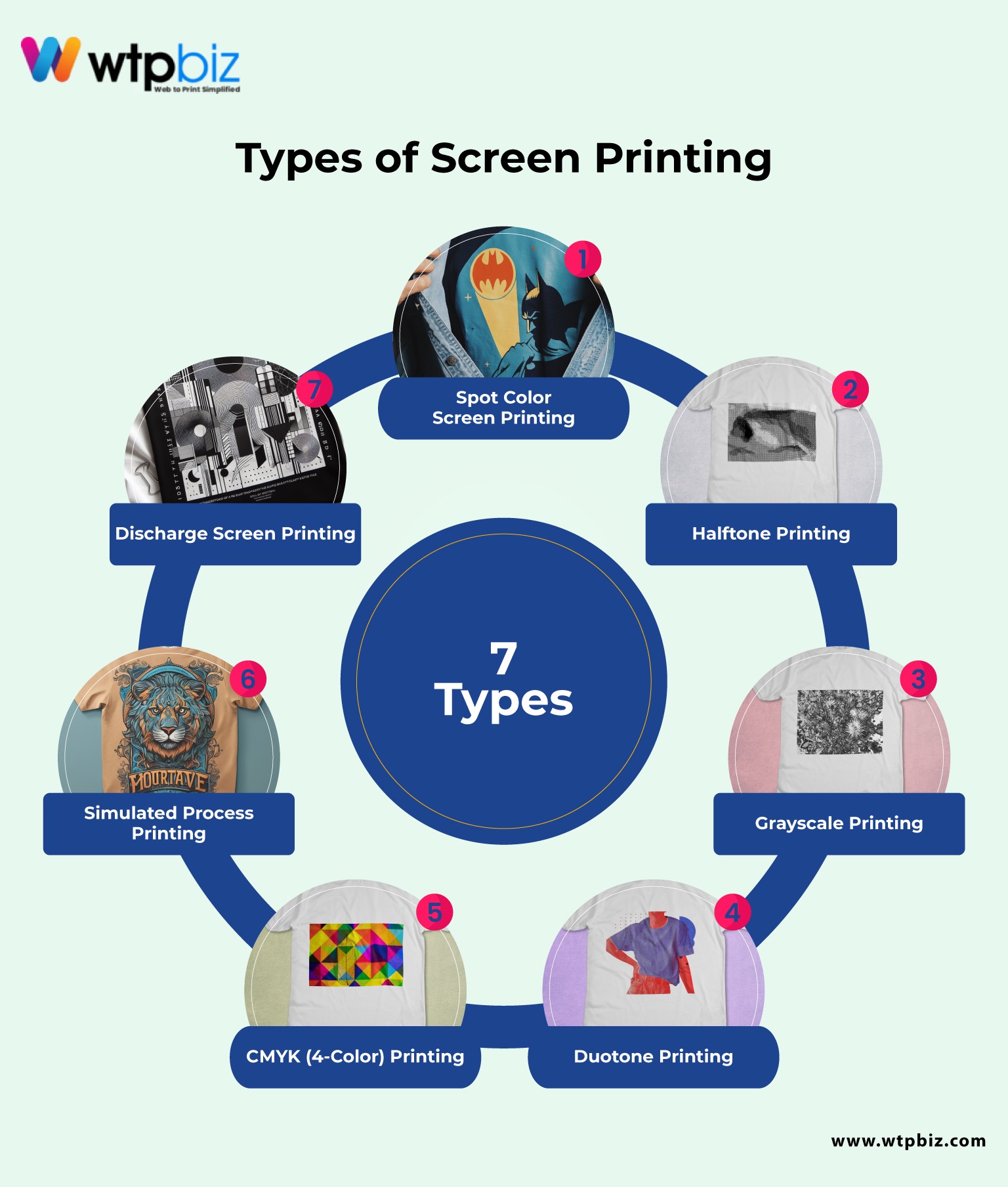

In this blog post, we will cover seven of the most common screen printing techniques, along with their unique characteristics and best-use cases, to help designers and print businesses choose the perfect technique to match their needs. From big and bold designs to the slightest artwork, there's always a method to make that happen.

Types of Screen Printing

Screen printing is a flexible and widespread technique for applying high-quality designs to numerous mediums.

1. Spot Color Screen Printing

Summary Definition: Spot color screen printing refers to using discrete colors, one by one, to print an image wherein each color is printed via a separate screen.

Comprehensive Description of the Process

One of the most common methods is spot color screen printing, especially with simple designs with solid blocks of color. Here's how the process works:

Design Separation: The design gets separated into its component colors, and each color gets a separate screen.

b. Screen Preparation: A mesh screen coated with emulsion is exposed to light to create a stencil of the design for every color.

c. Ink Application: Using a squeegee, one color at a time, ink is pushed through the screen onto the surface of the garment or material.

d. Curing: The design is then cured, usually with heat, to set the ink and ensure its longevity.

Advantages and Disadvantages:

Advantages:

Clean, crisp lines with vibrant, solid colors.

Designs with few colors are relatively inexpensive.

Durable enough, especially on fabrics.

Disadvantages:

Gradients and shading do not lend themselves well to screen printing.

Limited flexibility with color transitions makes complex designs hard to print.

Best Uses for:

Spot color printing is ideal for designs that do not require many colors, such as logos, words, and simple graphics with less color. It is common in T-shirt printing, promotional merchandise, and sports jerseys.

Real-World Applications

Classic logo T-shirts for brands like Nike and Coca-Cola often use spot color screen printing extensively for their bold and iconic designs.

2. Halftone Printing

Brief Definition: Halftone printing creates shading and gradient effects through small dots for greater design detail and a subtler color transition.

Expanded Explanation of the Process

Design Conversion: The software uses the design to convert the design into a pattern of dots. Every dot is considered to be part of the image; its size or density determines whether the gradient appears smooth.

b. Screen Preparation: A mesh screen is prepared with an emulsion similar to that used in spot color printing but with a tiny dot making the image.

c. Ink Application: The ink is pressed through the screen. Dots of the ink will make the varied color intensity on the material.

d. Curing: This will be cured using heat, like that used in spot color printing, so that it sticks and lasts longer.

Advantages and Disadvantages:

Advantages:

Suitable for images with gradients, like photographs or intricate illustrations.

Enables more detailed and high-quality images.

Disadvantages:

Less color accuracy compared to spot color printing.

The dot pattern can be visible on very large prints, which may affect the overall smoothness of the design.

Best Uses:

Halftone printing is often used for complex designs, such as photo-realistic prints, magazine covers, and detailed illustrations on garments.

Real-World Applications:

Band T-shirts with image albums or portraits, such as those about The Beatles or Pink Floyd, are more likely than not to use halftone printing to recreate the designs of these band's album covers with gradients.

3. Grayscale Printing

Definition Brief: Grayscale screen printing utilizes a gradient of different shades of black to generate the impression of depth and dimension, but without applying color.

Elaboration on the Process:

Preparation in Design: The original design is turned into a grayscale version, utilizing only black, white, and different gradations of gray to denote the colors originally used.

b. Screen Creation: This design separates into different grayscale layers that correspond to a certain amount of ink density.

c. Printing: One layer is printed at a time, utilizing the black ink in varying thicknesses for the effect of gradient

d. Curing: The printed design would be cured with heat to fixate the ink. Advantages and Disadvantages

Advantages and Disadvantages

Advantages:

It is best used for designs that do not require colors to emphasize their depth through shades of black.

It is very suitable for subtle shading and depth effects.

Disadvantages:

It is limited to black-and-white designs, hence less ideal for colorful artworks.

It is less vivid compared to other full-color printing techniques.

Ideal Applications

Grayscale printing is very effective in minimalist designs, black-and-white photographs, and any artwork that depends more on tonal contrast than color.

Real-World Examples

Grayscale printing is used for graphic T-shirts, or album covers that use black-and-white imagery with high contrast, like old punk rock designs.

4. Duotone Printing

Short Definition: Duotone printing uses two colors to produce a more vibrant and dynamic look compared to standard black-and-white printing, which often uses shades of the same color.

Detailed Explanation of the Process:

Design Conversion: The original image is divided into two primary colors, which can be two different colors or different shades of the same color.

b. Screen Creation: Create two different screens for each color, each capable of applying the respective colors in layers.

c. Color Application: Apply the first color of the design to it, followed by the second color for a duotone effect.

d. Curing: The design is heat-cured after printing to lock in the color.

Advantages and Disadvantages

Advantages

It presents a more dynamic visual effect of the design than even black-and-white printing alone.

It uses only two colors but can produce a much wider range of tones.

Disadvantages:

Limited to two colors might not be ideal for designs requiring more intricate color schemes.

It's less vibrant than full-color or CMYK printing.

Best Uses:

Duotone printing is often used for high-contrast designs such as posters, band merch, and retro-style graphic T-shirts.

Real-Life Applications:

Music posters or limited-edition band shirts are great examples of using duotone printing to create bold, high-contrast designs with just two colors.

5. CMYK (4-Color) Printing

Definition Summary: CMYK printing applies four colors, cyan, magenta, yellow, and black, to build up a full spectrum of colors by overlapping ink layers.

Detailed Explanation of the Process:

Design Conversion: The original design is broken into four color channels: cyan, magenta, yellow, and black.

b. Screen Preparation: Separate screens are prepared for each of the four colors.

c. Ink Application: Each color is printed in layers, with the colors overlapping to create new hues.

d. Curing: Like others, the ink is cured at heat for strength.

Benefits and Drawbacks:

Benefits:

Able to print with full-color images that result in having very high-quality and extremely vivid images.

Best method for complex designs with colors.

Drawbacks:

It is slightly more costly and time-consuming compared to other ways, especially in smaller sizes.

It may be less detailed for very detailed designs like fine gradients.

Best Practice Uses:

Photographic and artwork images are best when a wide range of colors is required.

Examples in Real-World Applications:

High-quality promotional T-shirts and art prints may require CMYK to provide photorealistic results.

6. Simulated Process Printing

Brief Definition: Simulated process printing uses a sequence of halftone dots and spot colors to mimic the appearance of full-color designs, especially on dark fabrics.

Detailed Explanation of the Process:

Design Separation: The design is separated into halftone layers and spot colors that replicate the appearance of a full-color image.

b. Screen Preparation: Screens are prepared for each halftone layer and spot color.

c. Ink application: It is done in multiple layers where the halftone builds depth and shading while spot colors fill the design. After curing, the print is cured through heat using a design for long-lasting quality.

Pros and Cons

Pros

Good for prints full-color designs on dark shades of fabrics.

Permits highly detailed and rich graphics design that does not need complete CMYK printing.

Cons

It needs perfect matching for the color and is more complex in operation than traditional spot color print.

It is more expensive than any ordinary screen printing technique.

Suitable Applications

Simulated process printing is used for intricate, multi-colored prints on dark or black fabrics, such as customized T-shirts and other detailed print apparel.

Real-Life Examples

Some custom T-shirts with elaborate graphics or band logos on dark fabric always use this type of printing.

7. Discharge Screen Printing

Brief Definition: Discharge screen printing is an ink that actually pulls the dye out of the fabric, creating a softer print with rich, vintage-style colors.

Detailed Explanation of the Process:

Ink: A discharge ink is used, which removes the dye from the fabric and replaces it with the printed color.

b. Screen: Separate screens are made for each color in the design, just like with other types of screen printing.

c. Dye ink: Applying discharge ink removes fabric dyes and replaces them with new colors.

d. Curing: It is cured using heat to fix this art on clothes while keeping the softness intact.

Pros and Cons

Pros

It looks at soft, distressed clothes as the ink coats aren't thick.

It is best applied for light-colored fabrics because a distressed or faded impression must be created.

Cons

It is not suitable for dark-colored fabrics since it relies on removing existing dye.

More precise control is required, and a design may fade over time.

Best Applications:

A great application of discharge print is in vintage-style clothing, most especially soft, worn-in tees.

Real-World Examples

Use discharge screen printing, especially in vintage band shirts and retro-style garments.

Factors to Consider When Choosing a Screen Printing Method

Several critical factors guide you in choosing a screen printing technique for your project. These considerations would impact the print's quality and cost and ensure that the final product satisfies your creative and business needs. Here are the most important elements to consider:

1. Number of Colors in the Design

The intricacy of your design will affect the cost and method you choose for printing. Consider using techniques such as CMYK (4-color) or Simulated Process Printing for designs with many colors, as they can reproduce a wide range of shades.

On the other hand, methods like Spot Color Screen Printing may be more appropriate for designs with fewer colors because each color requires a separate screen. Generally, more colors result in more expensive production and longer lead times to set up for intricate designs.

2. Print Area and Placement

The placement of your design on the garment or product determines which screen printing method is best suited. Larger areas or all-over prints demand a more flexible printing technique to cover broader spaces without distortion.

Discharge Screen Printing will be the most appropriate in such cases. On the other hand, for smaller designs or localized prints on T-shirts, hoodies, or other garments, it might be cost-effective with Spot Color or Halftone Printing, as these methods offer precision for smaller prints.

3. Type and Quality of Garment or Material

The fabric or material to be printed can determine which type of screen printing to use. A traditional Silk Screen Printing technique can work very well on t-shirts, mainly using cotton or cotton-blend fabrics.

Discharge Screen Printing or Simulated Process Printing could be preferred if the color used needs more intensity on a darker background for it to come out really intense and not fade fast. Fabrics such as polyester or blends may need specific inks. Therefore, the method must suit the material type.

4. Quantity for Order

Large orders greatly help lower the price per piece of printing. Methods in screen printing that work well with large print orders include Spot Color Screen Printing or Halftone Printing since the quantity of order shares the setup cost involved.

Digital or Direct-to-garment printing works better if you have less quantity for order.

5. Desirable Look and Feel

Consider how the final product will feel. Some techniques—halftone printing or simulated process printing—come to mind, and they will inherently result in a softer feel than print, especially when applied to lightweight fabrics.

While Spot Color Screen Printing may involve more raised profile ink, this can sit quite visibly on the textile.

6. Sustainability Requirements

It can get very environmentally friendly nowadays by using water-based inks or low-emission screen printing. There are still some options for businesses where even the printing method can benefit the environment. Such types, like discharge screen printing, are done using environmentally friendly chemicals, meaning a soft finish and more Earth-friendly.

By carefully considering these factors, designers and businesses can make informed decisions that balance cost, quality, and environmental impact while achieving the desired effect for their projects.

Conclusion

Screen printing is still an excellent choice for many purposes, such as T-shirt and garment printing. Knowing the differences between spot color, halftone, and CMYK printing ensures that you can make the right choice depending on the design, material, and budget. The different types of screen printing provide unique advantages in terms of colorful prints, durable prints, and low cost, making them an important resource for designers and printing businesses.

Lastly, the correct selection of screen printing method would imply choosing based on such factors as design complexity, type of material, and order sizes. Ready to bring your design to life? Try our web-to-print solution today for seamless, professional results.

FAQs

What is the difference between screen printing and digital printing?

Screen printing applies ink in layers using mesh screens, while digital printing transfers ink directly onto the fabric using printers. Screen printing is recommended for large orders with solid colors, while digital printing is preferred for intricate designs and full-color designs.

What is the most durable type of screen printing?

Spot color screen printing is the most durable when applied to good-quality garments. The ink is more resistant to fading and thus does not fade easily after a few washes.

How long does a screen-printed design last?

With proper care, screen-printed designs last for years. However, this will depend on factors like the type of ink, the quality of fabric, and the methods used for washing. Most of the time, quality prints last between 30 and 50 washes.

Can I screen print on dark-colored fabrics?

You can screen print on dark-colored fabrics. However, an underbase layer of white is required to ensure that the colors on darker backgrounds appear bright and sharp.

What file format is best for screen printing?

EPS, AI, and PDF are ideal for screen printing because they contain vector file formats. They maintain the image resolution and are scalable, thus giving clear and clean prints on the garments and other products.

FAQs